Introduction

Sterile Processing Departments (SPDs) are the unsung heroes of surgical safety. Tasked with the meticulous preparation of surgical instruments, they serve as the final checkpoint before tools reach the operating room (OR). Yet, despite their crucial role, many SPDs operate without systematic oversight. A multi-facility audit reveals a concerning gap: among 200 healthcare facilities analyzed, only 93—fewer than half—have implemented a proactive auditing process to validate tray readiness before surgery.

The Risk Landscape

Sterile processing is high-stakes work. Tray errors—whether from bioburden (residual biological material), moisture, or foreign objects—can result in procedural delays, regulatory violations, and worst of all, increased risk of surgical site infections (SSIs). A comprehensive study spanning over 185,000 proactive audits conducted across 93 facilities found a 2.0% failure rate, equating to 3,700 defective trays that were caught before reaching the OR.

Breakdown of Detected Defects:

-

Foreign Items Present: 30.5%

-

Bioburden Present: 18.7%

-

Moist Packaging: 4.2%

Each failure type represents a potential sentinel event. Without proactive checks, these defects would have entered surgical suites unnoticed.

The Power of Proactive Auditing

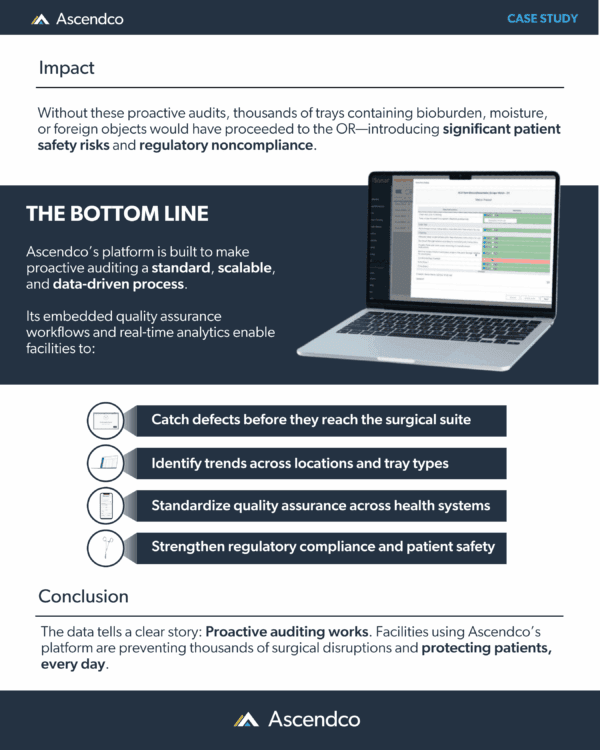

Facilities using structured auditing programs are proving that data-driven oversight yields measurable safety outcomes. These systems enable:

-

Real-time detection of tray defects

-

Standardized quality assurance across locations

-

Root cause identification via analytics

-

Regulatory compliance reinforcement

According to audit data, these proactive facilities prevent over 1,500 bioburden incidents annually, directly supporting reduced SSI risks.

Operational & Clinical Benefits

Beyond infection prevention, proactive auditing delivers operational wins:

-

Fewer procedural delays through timely instrument availability

-

Improved OR scheduling due to reduced reprocessing time

-

Stronger training programs based on audit feedback

-

Lower human error rates due to visibility and accountability enhancements

In one case study, facilities employing Sonar-SQ.track saw improvements in workflow standardization, staff education compliance, and APIC-aligned practices.

From Blind Spots to Benchmarks

Facilities without auditing systems continue to show higher SPD failure rates and missed learning opportunities. Proactive audits, on the other hand, uncover systemic blind spots, from undertrained staff to untracked sterilization steps. The repeatable audit-to-quality loop fosters a culture of continuous improvement.

Conclusion

The evidence is clear: Proactive auditing is not just a nice-to-have—it is a surgical safety imperative. SPDs equipped with audit workflows are not only intercepting dangerous errors, they’re transforming their departments into strategic partners in patient safety.

As surgical volume increases and complexity grows, the path forward demands data-driven transparency, standardized quality checks, and cross-functional accountability. Proactive auditing empowers SPDs to live up to their role as the true gatekeepers of the OR, protecting patients, every single day.